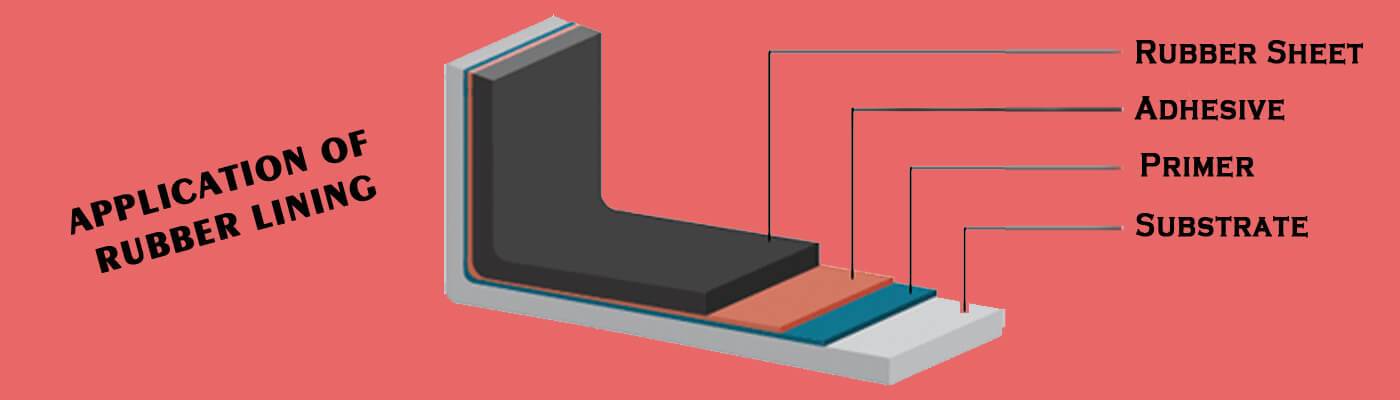

Rubber lining is the skilled application of unvulcanized rubber sheet to prepared metal surfaces. The lined items are then vulcanized in a steam autoclave, fully bonding the rubber to the metal surface creating a durable and resilient protective rubber coating.

The rubber coating can be from 2mm to 50mm thick depending on the application, and can be bonded to mild steel, stainless steel, cast iron and aluminum.

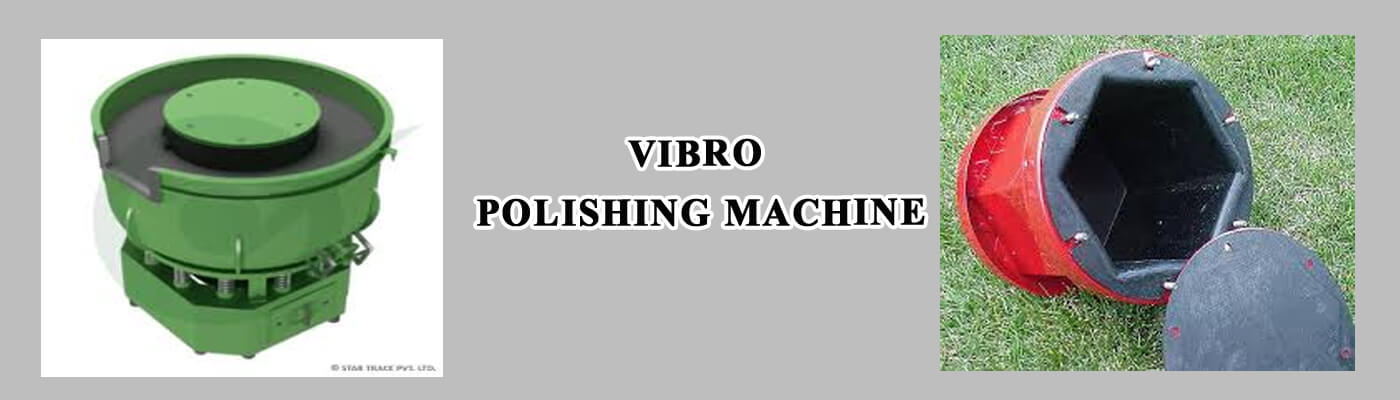

The principal benefits of rubber lining are its excellent resistance to corrosive and abrasive chemicals and materials, e.g. acids, alkalis, salt water, slurries, sand, shotblast media, crushed rock etc. In addition rubber linings provide other benefits including noise and vibration reduction, electrical and thermal insulation and product protection

We have experienced staff to carry out any rubber lining work with utmost quality .